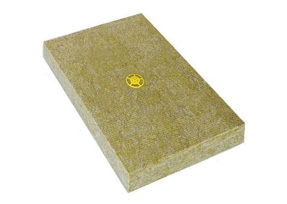

Where to use rigid panel insulation:

Rigid panel insulation is often found attached to the footing and exterior backfill of foundation walls. These panels may be coated to protect the exposed exterior foundation wall from sunlight and moisture. Other common places to use this insulation are under or on top of the roof sheathing.

Rigid panel insulation is ideal for tight conditions where a high R-value is required. It is particularly ideal for cramped spaces. Rigid panels are appropriate for making the foundation damp proof. In addition, they further strengthen the wall. These insulating panels may also have a radiant heat barrier foil, which helps in reflecting solar and infrared energy before it penetrates a wall or ceiling, thus improving the insulation property of the panels.

Types of rigid panel insulation:

Extruded expanded polystyrene (XEPS) boards are the most common panels. They are made from closed cell foam consisting of a foaming agent and liquefied polystyrene pellets, which is poured into a mould and set. On cooling, the panel is cut into desired shapes and sizes. The average density of these boards is usually 1.5 per cubic foot. Another common type of rigid panel insulation board is molded expanded polystyrene (MEPS) foam board, commonly known as beadboard. These beadboards are also made by a process in which the molten foam is poured into a mould, set, and cut into boards of standard sizes. XEPS boards are more expensive as compared to MEPS boards.

Two other types of rigid panel insulation boards are Polyisocyanurate and Polyurethane boards. These boards are considered the ideal solution where space restriction is an issue. Polyiso boards are known for their ability to remain stable over a broad temperature range. Hence, they are often used for roof insulation. On combining with aluminum foil, these boards can also be used as effective vapor or moisture barriers.

Things to remember when handling rigid panel insulation boards:

Rigid insulation boards should be kept placed tightly together and the seams should be sealed with caulk or tape. These boards are usually placed between the exterior finish and the studs of the exterior wall. These boards not only ensure that the house is thermally insulated but has acoustic insulation as well. Today insulation boards are being made of recyclable ingredients.

These boards often fall prey to UV damage. All insulation boards are flammable and produce toxic fumes when they burn. Due to this, they need to be covered with fire resistant gypsum board. Insulation boards are more expensive than any other form of insulation.