System working:

In a CHP system, fuel such as natural gas is burnt to produce heat and electricity simultaneously. The electricity generated can power devices like house lights and appliances while heat produced is put to heating purposes. CHP units mostly use either internal combustion engines or external combustion engines like Stirling engines for generating electricity. Residential CHPs are also known as Micro-CHPs; they use a number of fuels including propane, natural gas, concentrated solar energy, biomass, etc.

Heat Generation:

A large amount of heat is produced in the electricity generation process. This heat finds application in home heating, water heating or even in absorption cooling systems. CHP systems are highly efficient. They generate up to 90 % of power and heat with in comparison with 40% generation efficiency from conventional power stations.�

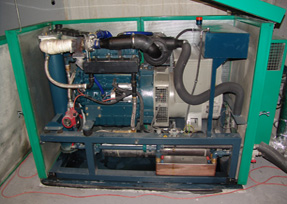

Micro-CHP units:

Micro-CHP units are available in capacities ranging from 1 kW to 6 kW. Currently, most micro-CHP units are designed to connect with utility power as a backup system. However, in some areas, stand-alone systems are available. A unit with a small capacity engine can generate 1.2 kilowatts of electric power and 11,000 Btus of heat as heated water. A boiler or furnace that runs on natural gas may provide additional space heating.

���

The small engines are clean burning and exceed emission requirements for CO2 and Nitrogen-based gases. There are also CHP units that produce smaller amounts of carbon monoxide and nitrous oxides than the average burner on a kitchen gas range. To get the highest efficiency out of a micro-CHP, it is important to fully utilize the heat energy produced during electricity generation. This aspect is being studied and various operating regimes are being tested to optimize the energy available for domestic use.