The origin of aerogel:

The first aerogels were prepared as early as 1931 by NASA. Aerogels are silica gels (or gels of other metal oxides) which have their liquid content removed by a process of super critical drying.

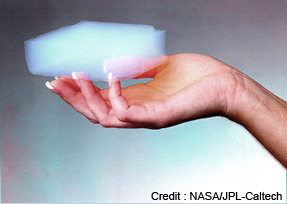

Aerogel is a semi-transparent, brittle material. It feels something like Styrofoam; the material disposable cups are made of. Aerogels are extremely lightweight as they consist of 97% air and weigh only 90g per liter. It has a high insulating R-value of 250 or better.

How Aerogels work:

Aerogel is such an effective insulating material that astronauts in space are using it. A mere 18mm of aerogel is sufficient to insulate an astronaut to withstand a temperature of–130°C. Where physical space is a constraint aerogel can prove to be an ideal alternative. A thin layer of aerogel will easily outperform a traditional insulating blanket. Aerogel also has a very good fire resistance capability. One of the disadvantages of using aerogel insulation is that the shape that it is available in is limited. Aerogel is manufactured in round, oval, or cylindrical shape.

How aerogels save energy:

Aerogel is a new age structural insulating material that is being developed. It is a very effective insulating agent because it manages to nullify effect of heat transfer by convection, conduction and radiation. This means that the material prevents heat from flowing through the material, or heat being transferred by the movement of air or heat being transferred by infrared radiation. Aerogel has a thermal insulating quality equivalent to 10 – 20 glass windowpanes. This accounts to an overall energy saving of 30% for households. If windows were made of aerogel, it would significantly lower heating bills by preventing unnecessary heat loss or gain. The super low density of the material ensures that it is ideal as a lightweight structural material. This combined with its super high internal surface area; Aerogel can be used as a very good insulating material.

Various types of aerogel insulation and how to use them:

Today, aerogel blankets have become commercially available. These are made of a composite of silica and aerogel and a fibrous reinforcement that turns brittle aerogel into reinforcing fibers. The main application of aerogel is still for industrial purposes. The basic form of an aerogel insulation system is a blanket. This blanket is made of aerogel-based radiation shield layers along with a low thermal conductivity aerogel / fiber matrix. The common shapes of aerogels that are available are blanket, sheet, sleeve, or clamshell shape. These blankets of aerogel can be used as substitutes to multi layer insulations. Sheets or sleeves of aerogel are also available. These add a backing material or outer skin over existing insulation. This will act as a weather barrier to prevent condensation of moisture or air escaping. Aerogels also provides additional safety and strength during the installation and improves durability in harsh environments.